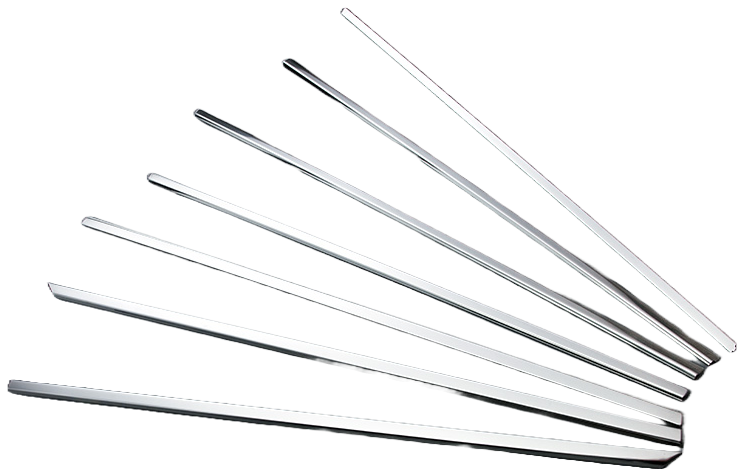

BRIGHT TRIM PARTSFOR THE AUTOMOTIVE INDUSTRY

Spectacular

Looking Parts

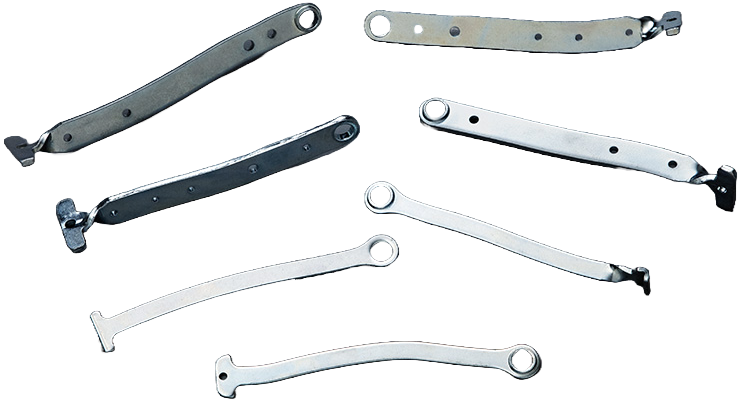

Bright Trim Parts & Precision Mild SteelFOR THE AUTOMOTIVE INDUSTRY

Magnificent

Looking Parts

BRIGHT TRIM PARTSFOR THE AUTOMOTIVE INDUSTRY

Magnificent

Looking Parts

BRIGHT TRIM PARTSFOR THE AUTOMOTIVE INDUSTRY

Magnificent

Looking Parts

BRIGHT TRIM PARTSFOR THE AUTOMOTIVE INDUSTRY

Magnificent

Looking Parts

Bright Trim Parts & Precision Mild SteelFOR THE AUTOMOTIVE INDUSTRY

Magnificent

Looking Parts

welcome to

Trim Stamping

Precision

Understanding Your Needs

Parts Stamping

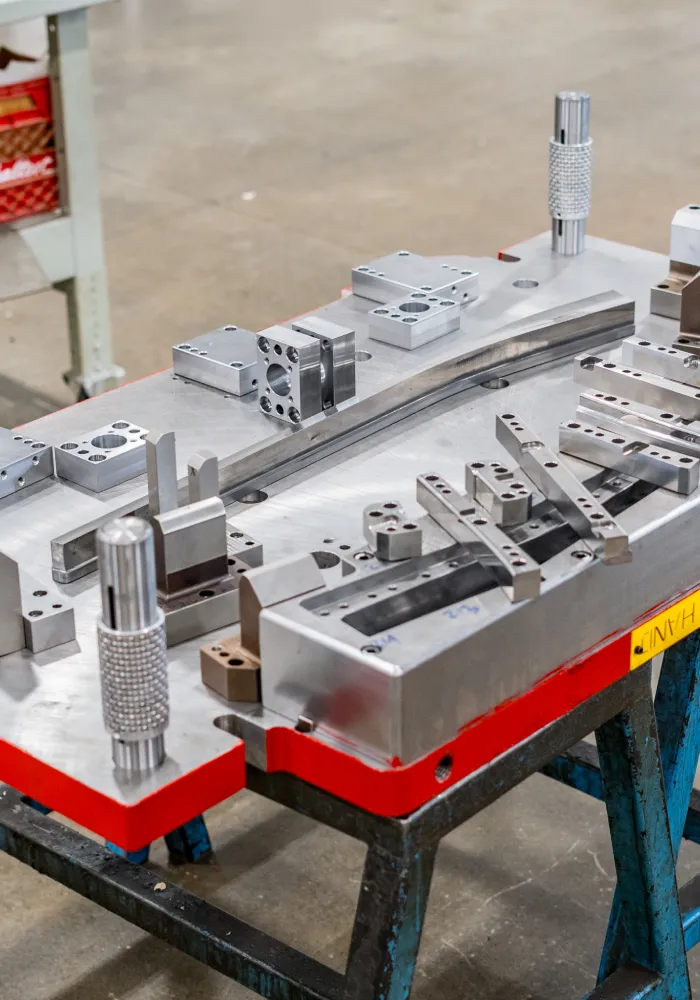

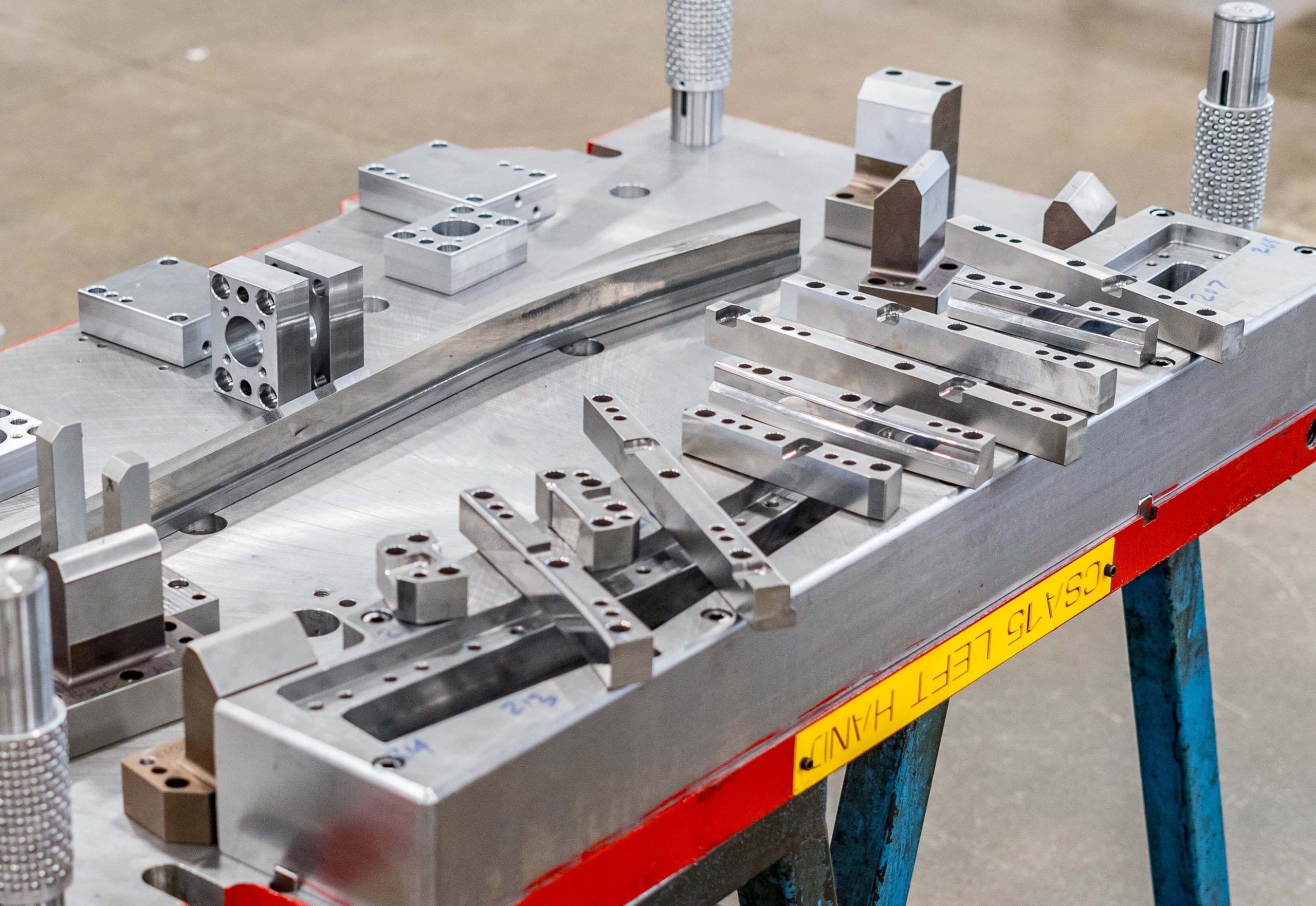

Tool & Die

In-House Control of Tool & Die Builds

Our distinction in the market stems from our comprehensive in-house capabilities in tool and die manufacturing. Unlike many competitors, we do not rely on overseas facilities for any part of our tool and die production. All tools are meticulously designed, built, and tested within our local state-of-the-art facility.

Quality and Precision

We ensure that all products we deliver meet the highest standards of quality and precision. This is possible because we handle every step of the manufacturing process.

Skilled Team Inspection

Each tool and part produced undergoes a rigorous inspection by our skilled team. This hands-on approach ensures that every detail is perfected before reaching our clients.

Promise of Perfection

Our internal processes and expert team collaboration guarantee that the final product is not just functional but perfected in every detail.

Our Products and Services

Parts Stamping Services

Mild Steel

Tool & Die Services

Proven Results